Introduction :

First of all, lower your volume and let's watch the video below where the GIF comes from. Enjoy ;)

Now that your computer just moved sideways, it's time to discover all the secrets of rocket engines!

Action/Reaction principle :

"To every action there is always an equal and opposing reaction: or the mutual actions of two bodies upon each other are always equal, and directed to contrary parts." Isaac Newton, physicist and mathematician

It is with this sentence that Newton announced the "action/reaction" principle in 1687 in his book 'Philosophiae naturalis principia mathematica'.

This principle will drive us through this article, because it states that a force created in one way will create a vector force (direction and intensity) opposed.

That way, throwing a heavy mass with a low speed, or a low mass with a fast speed will create an opposite force. Every so-called 'reaction' engine is based on this principle.

They are based on a fluid projection backward, which causes a forward thrust in reaction.

Two main types of reaction thrusters are currently used, depending on the origin of the matter which is thrown backward:

- The ones that throw the matter held within the device: rocket-engine, electric propulsion, photonic propulsion, etc.

- The ones that use a fluid which was already absorbed by the vehicle, in the front, and speed up, before being thrown backward, as the airliner engines (turbojets, turbofans), the ramjets or the scramjets, etc.

The thrust:

The thrust is the result of the ejection of mass from the rocket's rear at a certain speed.

In fact, the thrust is the result of the conversion of thermal energy located in the combustion chamber to kinetic energy when the gas flows through the nozzle (but we'll talk about that later).

The value of the thrust is given by the relation below : F = v.q + A.(P1-Pa)

- F, thrust in newton (N) -> The strength with which the engine "pushes" the rocket

- v, ejected gas velocity in m.s^-1

- q, mass flow rate (kg.s^-1)

- A, nozzle section area in square meters

- P1, nozzle exit pressure (Pa)

- Pa, ambient pressure (Pa)

To simplify, a high thrust means that the engine will accelerate the rocket quickly and easily.

Specific Impulse :

A very important characteristic for a rocket engine is the amount of thrust created by a kilogram of propellant burned and ejected. This relation is called SPECIFIC IMPULSE (Isp).

Basically, it measures the force created by the spacecraft depending on the quantity of propellant consumed per unit of time.

Here is the mathematical expression : Isp = F / (g . q)

- F thrust in newton (N)

- g standard gravity in m.s^-2

- q mass flow rate in kg.s^-1

To simplify even more, the specific impulse allows one to know the efficiency of a propulsion system: the higher it is, the more efficient the system will be.

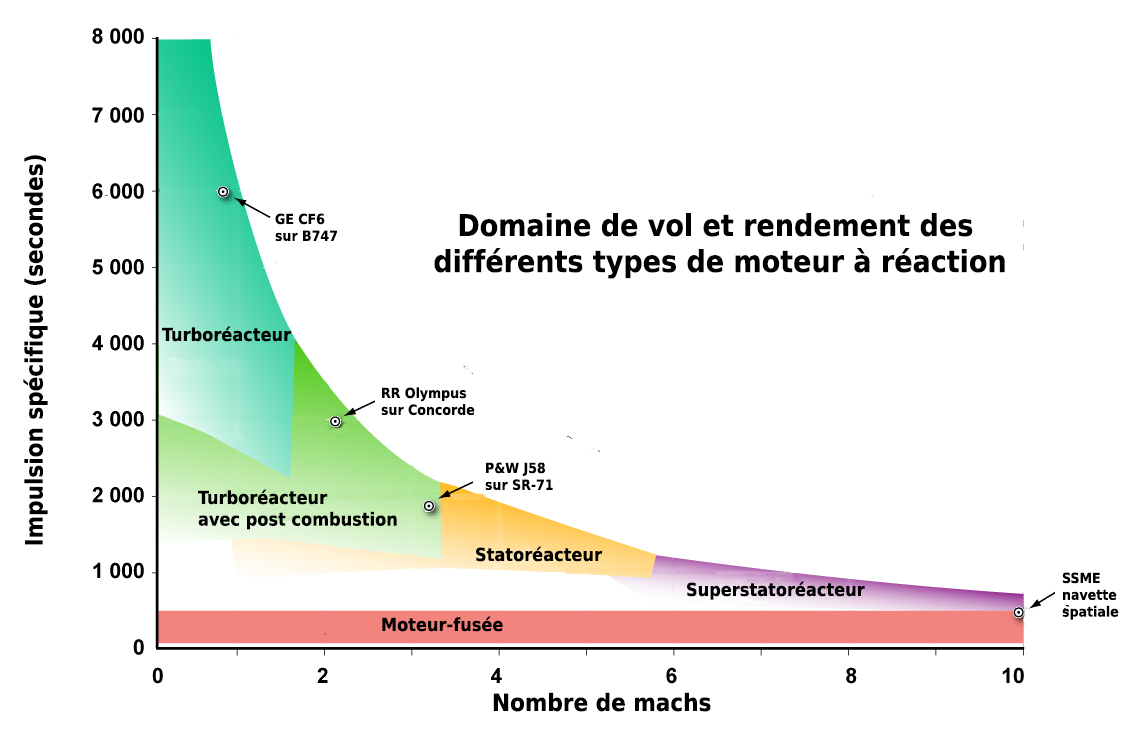

The value of the specific impulse for different types of reaction engines:

Thrust/Specific impulse relation:

We can't have everything in life! That why combining big thrust and big specific impulse is almost a myth.

At equal thrust, the higher the specific impulse is, the less propellant it consumes. However, less propellant in the combustion chamber means fewer chemical reactions happen and the thrust will decrease.

Some figures: let's take a Merlin1D+ engine from the SpaceX's Falcon rocket. Its specific impulse is +-350 seconds and its thrust is 845 kN. The combination of these two parameters is great, that allow the rocket and its payload to take off without burning too much propellant.

The nozzles:

I could write a WHOLE article about rocket's nozzles.

This is the component that the general public think is "the engine" of the rocket. This is only the most visible element, but not necessarily the most simple!

In general:

The goal of a nozzle is to speed up the gases created by the combustion in the combustion chamber of a rocket engine or even in a fighter jet engine for example.

Let's focus on the nozzles mounted on rocket engines.

Most of them are "de Laval nozzles". The gases will go through a channel that will narrow and then increase. In the narrowing gases speed up. But, the gas speed cannot exceed the speed of sound (Mach 1).

Indeed, at a supersonic flow rate (speed exceeding the speed of sound) the gas behaviour inverts : the speed increases when nozzle's diameter increases also. This means that a nozzle can be convergent, divergent or at the same time convergent then divergent :

-

A convergent nozzle allows to speed up gases flowing at subsonic speed. If there is enough pressure, the speed can reach Mach 1 at the end of the nozzle but it cannot overtake this value.

-

A divergent nozzle allows to speed up gases which are already at a supersonic speed when they enter it.

-

A convergent and divergent nozzle becomes a "de Laval nozzle".

De Laval nozzles :

A de Laval nozzle allow to speed up gases from a subsonic speed to a supersonic speed by combining effects described above.

Gases are speed to Mach 1 in the convergent section of the nozzle and then speed up above Mach 1 in the divergent section. So, a de Laval nozzle has three sub-assemblies :

- the convergent one where the diameter is narrowing, connected to the combustion chamber,

- the neck where the diameter is at the minimum,

- the divergent one which can be shaped like a cone or a bell, this is the most visible part of the nozzle.

Here, the red curve shows the temperature, the green one the gases pressure and the blue one their speed. Indeed, the nozzle transforms their thermal energy (and their linked pressure) into kinetic energy. At high-speed ejection, thanks to action/reaction, the rocket will rise up.

In practice, the speeds of the burned gases are between the following values:

- 1 700 to 2 900 m/s for liquid monopropellant rocket engines

- 2 900 to 4 500 m/s for liquid propellant rocket engines

- 2 100 to 3 200 m/s for solid propellant rocket engines

We will come back later to all these sorts of engines.

Compromises between nozzle shape and performance in relation to altitude :

Because the nozzle is used to adapt the gases pressure with the air pressure, if the nozzle does not change its shape, when taking altitude, the outdoor pressure will decrease and the exit pressure will not be perfectly adapted to the environment.

These differences between pressures create a loss of efficiency.

Diagram showing a rocket engine nozzle rating uses in relation to the gap between exit pressure gases from the divergent and the outside pressure. From left to right :

- 1: Gases are under expanded at the divergent exit : ambient pressure is below gases pressure

- 2: Adapted nozzle : exit gases pressure and ambient pressure are equal (optimal rate)

- 3: Gases are over expanded at the divergent exit (ambient pressure is too high)

- 4: Gases are grossly over expanded at the divergent exit with detachment of the flow all along the divergent wall (ambient pressure is really too high, situation where an optimised vacuum nozzle is turned on in the air)

Some bonus :

Very optimised nozzle can be really long. This way, some nozzles are deployable in flight before the engine is turned on. On the rocket, an extension comes down and settle on the original nozzle.

The thrust needed to propel a rocket is huge : it can reach 800 tons for liquid propellant rocket engines and 1500 tons for solid propellant rocket engines.So, to have that kind of thrust, the materials used have to withstand great pressures and temperatures. The conception of a nozzle is mostly based on the creation of cooling methods and the selection of adapted materials.

All the propulsive force of the rocket is applied on the nozzle, which create maximum mechanical pressure at the level of the neck. If we use an analogy, we could say that all the weight of the rocket (which can be hundreds of tons) push exclusively on the neck of the nozzle !

Can we have better nozzles ?

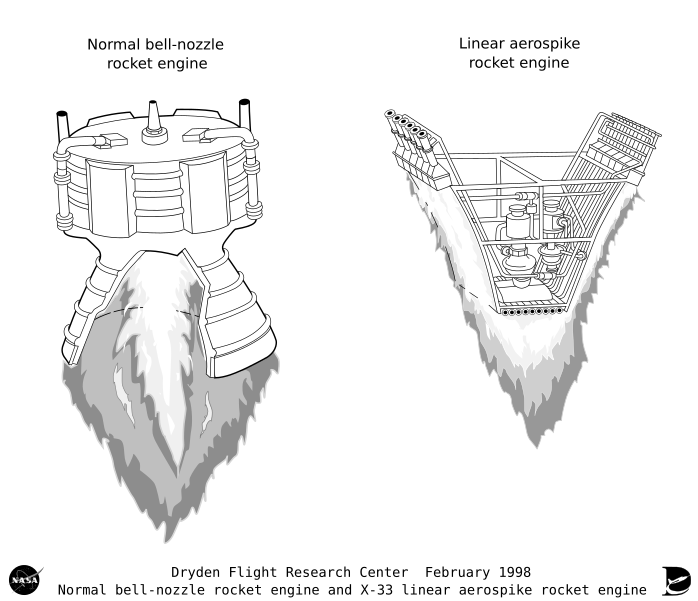

Some rocket nozzles are under study and could better respond to the pressure problem than extensive nozzles.

These nozzles, called "Aerospike" are able to optimise the propulsion efficiency in various ranges of altitudes.

A rocket engine that is equipped with an aerospike nozzle would use 25 to 30 % less fuel in low altitude (this is where rockets need a more important thrust). This kind of nozzle is under study since the beginning of spatial era but its development is slowed down because of the ramp (which direct the gas jet) cooling issue. Only prototypes of this kind of nozzle have been built.

Similarities between rocket engines and “classical” engines mounted on planes :

Planes which have jet engines, military or civil, have similar engines than rockets, except the fact that their nozzles don’t have a divergent (gases just go out by the neck of the nozzle) and that propellants used are less “explosive” : these planes fly thanks to lift not just vertical propulsion.

However, some planes have afterburners. This is a system used by supersonic military planes to temporarily increase the turbojet thrust.

This method consists in injecting and burning, thanks to backup burners, kerosene behind the engine turbine (which explain the term “after”) in the exhaust gases of the jet engine, which implies a massive increase of the thrust. In response, the propellant consumption increases a lot as well.

You can see it working on these two M88-2 engines from the French Rafale. These turbojets produce a 50kN “dry” thrust and thanks to afterburners it can reach 75kN (to be compared with the thrust of ONE Merlin, which is 845kN ; however they don’t have the same goal!)

You can find this photo on my Flickr : Space_Baguette

You can find this photo on my Flickr : Space_Baguette

The nozzle of these planes can often change their shape : the cone creating the nozzle neck move in order to increase or narrow the nozzle neck diameter, by speeding up “dry” gases or leaving the afterburner’s flames pass.

Different types of rocket engines :

Now that you know the basics, I will focus on all the aspects of every engines that we find on rockets and even on probes and on satellites.

Here is the table of contents :

- Cold gas engines

- Solid propellant engines

- Liquid propellant engines

- Nuclear engines

- Ionic engines

- Other (EM Drive, internal combustion engines...)

Cold gas engines :

Principle :

Cold gas propulsion is a spacecraft propulsion method used to do small orientation or speed corrections.

A cold gas propeller uses high pressure gas released in a nozzle which orients the thrust produced. Sometimes, this gas decomposes itself in a catalyst.

Cold gas propulsion allows to do very small and very short thrust. The system is very simple because valves are the only mobile pieces and there is no burning of propellant. That's why it's highly reliable.

But the exit speed is slow, about 800 or 1500m/s and the thrust cannot overtake 50 Newton.

Because of its characteristics, we use it usually in altitude control of a satellite or a space probe. They need really small boost but repeated a high number of times (even dozens of thousands for a space probe). They also consume a small quantity of propellant for the duration of the mission which makes the bad efficiency acceptable.

Often, we use helium or nitrogen and when an engine must be powerful (everything is relative), we use a catalyst and hydrazine

In practice :

Cold gas engines have an ISP between 50 and 170 seconds, a thrust between 0,05N and 20N, and are often used in orbit and attitude control. In the rocket guiding article we talked about them under the name “RCS” (Reaction Control System).

These engines are called “Cold gas” because, via the Venturi effect, the gas speed up and loose its heat and will (obviously) become very cold.

Solid propellant engines :

Principle :

Solid propellant propulsion refers to a propulsion technology which uses a compact powder. The powder block is drilled by a longitudinal channel that is used as combustion chamber.

When the propeller is turned on, the powder block surface start to burn creating high pressure combustion gases that are ejected by the nozzle. By giving a specific geometry to the channel we can, to a certain extent, define a thrust curve answering to the profile needed.

We can compare them to big unstoppable fireworks, very powerful but also really big eater. The ones from the Space shuttles were giving 71,4% of the total thrust (more than 300 tons must be sent to 7,7km.s^-1 !) but they were burning very fast (123sec).

Some of these engines can control the thrust orientation.

The nozzle can be mount on a gimbal like in the case of the Ariane 5 SRBs (Solid Rocket Boosters) for example. We can also use gas deflectors or inject liquids in the nozzle exiting gas jet.

In this case, a liquid is injected after the nozzle neck, a chemical reaction is happening with the generated gases and the adding of this non-symmetric thrust on one side of the jet create a torque that makes the rocket turns. For example, the solid propellant propellers from the Titan III C rocket use nitrogen peroxide to create this reaction.

In practice :

Solid propellers are often used to speed up the rocket at the lift off, they are the famous "Boosters" from the Space Shuttle or the SRBs on the Ariane 5. For example, these SRBs produce on average 550 tons of thrust during 129 seconds with an ISP of 240 seconds : their flying time is shorter than their ISP, so, they are profitable and powerful. They have a size of 31 by 3 metres and they are fuelled by a mix of ammonium perchlorate, aluminium and polybutadiene.

On the SaturnV rocket, these small solid engines were used to separate the two stage and press the liquid fuels against the pump's entrance, but we will come back on this in just a moment.

Let's take for example the Vega Rocket, the light rocket from Arianespace. Its first 3 stages (out of 4) are solid engines, like was the first stage of Ares1-X.

In conclusion, they are used as boosters, main stage or even small separation engines.

Liquid propellant engines :

Principle:

In the 1900s, Constantin Tsiolkovski had the idea to use for the first time a liquid propellant engine. These engines are now used in most of the rockets.

The combustion chamber is where the propellants are burning. The goal will be to apply a huge pressure in this combustion chamber in order for the gases to exit to a higher speed in the nozzle, creating a higher thrust.

The most interesting part of the combustion chamber is called injector and is use to spray the propellants to have a homogeneous mix. There are two types :

- Centrifugal injectors, in which the propellant is entering in rotation and scatter in small droplets when it exits, kind of hard to build.

- Linear injectors, in which the propellant is directly injected, less efficient than the first one but easier to build.

We can combine these both types of injectors to obtain combinations of propellants distribution. For example, we have coaxial injectors (pairing up a centrifugal injector and a linear one create an excellent mix), shaped like a shower head, crossed jet where the jets of many injectors are meeting and scattering (only with linear injectors)...

If the injectors are unstable, the flame and the propellants flow will be unstable too, which could lead to the loss of an engine !

Unlike solid propellant engines, they can be putted out. We only need to close the sluice gate that bring the propellants in the combustion chamber !

Liquid propellants mixtures :

Liquid propellants used must be stable, easy to stock and to use, and their mix must create (of course) a lot of exothermic energy.

There is a GIF, taken from a Falcon9 flight, that shows the liquid oxygen floating around in the tank, even after the engines have been shut down.

Moreover, we need to distinguish two types of mixtures. Two propellants that burn at the slightest touch are called Hypergolic. That allows to simplify the ignition. We just need to bring them in the combustion chamber and they ignite !

Otherwise, we need to add an engine starting device and its reliability must be maximised.

This ignition can be triggered by a pyrophoric fluid which light spontaneously, its flame ignites the propellants. A spark, a resistor, a catalyst or an explosive can also be used as an igniter. Some engines were even starting with explosive cartridges that made turbines turned !

Cycles and ignitions :

Liquid propellant engines must have different devices to bring the propellants into the combustion chamber. A way to ignite the mix is also needed.

All these methods are called "cycles" of combustion.

"Pressurised" cycle :

In this system, a gas tank is added beside the propellant tank and the combustive tank too.

This gas will pressurize the propellant tanks, "pushing" them at the bottom of the tank, bringing them in the combustion chamber. In order to maintain a stable and complete combustion, the tank pressure must be stronger than the combustion chamber one, which lead to very thick and strong tanks but also heavy.

These engines are rather "simple" and they don't need any turbopumps which are complex and sometimes unstable. To ignite them, we only have to open some valves. If the mix is not hypergolic, a lighter will be necessary. However, we can easily ignite multiple times these engines no matter is they are hypergolic or not.

Here, a hypergolic propellant engine that does not need any lighter.

Even so, we must be careful. The pressurized helium will expand and become cold, which could freeze some parts or the fuel. For example, in the case of the LEM engine from Apollo, it was preheated by a heat exchanger around the combustion chamber. However, the heated helium, like every hot gas, took more space and pressurized better the tanks.

A very famous pressurized cycle engine is the Kestrel, engine of the Falcon1 launcher from SpaceX.

This kind of engines is of course simple, but it is not very efficient, the tanks and the gas are also heavy, reducing the capabilities of the rocket. This is the cheapest cycle to develop. It's easy to ignite and reliable.

The gas used, often Helium, is a "noble" gas. Indeed, a noble gas (last column of the Mendeleiev periodic table) does not chemically react with the propellant, leaving it "intact" and ready to burn.

Gas generator cycle :

In this cycle, a "gas generator" is used.

This system is composed of a small combustion chamber linked to a pump. This chamber pumps a small amount of the rocket's propellants and the gas created by this generator is guide to a turbine, linked to the turbo-pumps.

To simplify, the engine burns an amount of its propellant to have the pumps turns that will bring the propellants in the combustion chamber. Then, this gas is drained away by an evacuation.

The main inconvenient is the loss of efficiency because of the gases that are not use to propel the rocket. Gas generator cycle engines have generally lower specific impulse than other cycles.

The "gas generator" cycle is also called "open" cycle because the gas is drained off without being useful for the propulsion.

Often, an amount of the propellants (that are very cold to be liquid et dense) is used to cool the nozzle. Even modern materials can't tolerate a such heavy pressure and heat, and if not being cold, the engine would explode in a very impressive but, most of all, in a very disastrous way.

There is a video of a SpaceX engineer who is talking about their Merlin engine, that uses this cycle : Tom Mueller (SpaceX) Explains The Merlin Rocket Engine.

On most of these engines, a gas keeps pressurizing the fuel, and some amount of it is heated up around the gas generator then sent in the tank in order to pressurized it. But why, if the pumps already bring the propellant? Look-up at the GIF : in zero gravity, the fuel is moving, and is not available at the entrance of the turbo-pump. So, the pressurization pushes them toward the pumps. As a reminder, if the turbo-pumps suck gas up, not a liquid, the engine would be damaged...

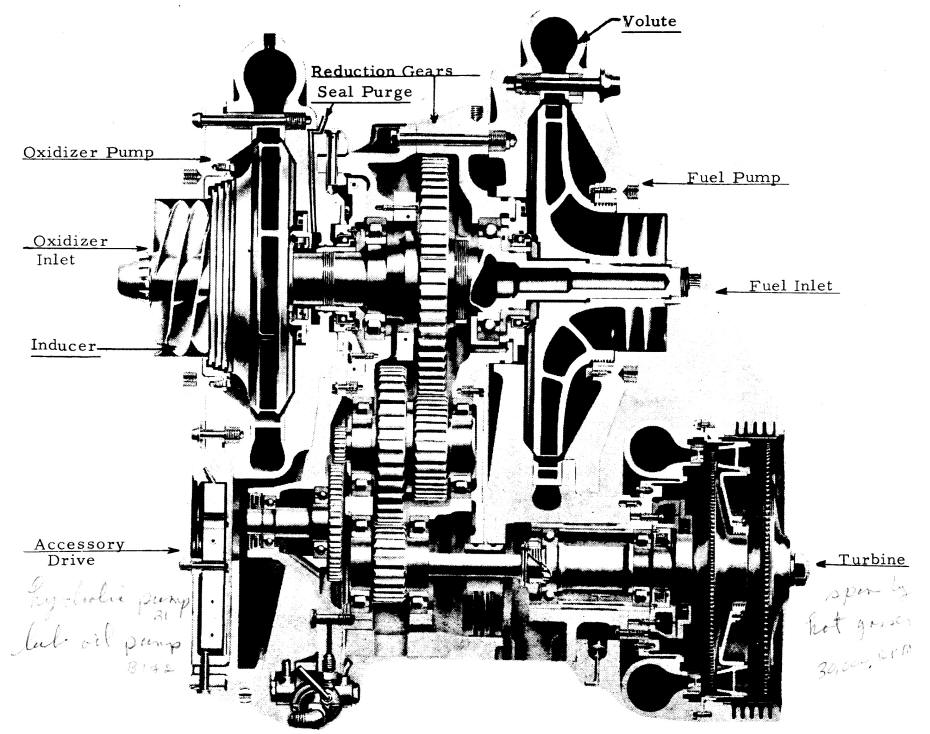

The Turbine/Pump group is in one block and camshaft, and is called turbo-pump. This system pressurizes the fuel 30 times more, between the tank and the injector !

In the case of the Merlin engine, the gas generator burns at 760°C, and ignites, like the combustion chamber, with a hypergolic mix (TEA-TEB). The turbo-pumps are now working, it brings the propellants (Kerosene "RP-1" and Liquid Oxygen "LOX") in the combustion chamber, which will reach 3300°C !

The thrust of this engine is 935kN, its ISP is 340 seconds.

Close cycle :

Close cycle engines work like open gas generator engines, the only difference is that the exhaust gases (the dark exhaust on the right of the photo above) are guide IN the combustion chamber. So, they are not lost for the thrust.

The best advantage of this cycle is that we increase the ISP, but it is really hard to develop.

Because, this time, the gas generator uses an enriched mix with fuel not oxidant. The gas that come back in the combustion chamber is highly flammable.

This "close" cycle does not lose any gas and reuse them. However, these gases are very complex to use and test the turbines and the pumps severely.

The gas generator and turbine pressures must be higher than the one of the combustion chamber, avoiding the flames to rush into where they should not be, that would, obviously, create an explosion.

This cycle is more expensive, more complex but, like for the open cycle, it reduces the weight of an engine and increase the performances.

Combustion bypass cycle :

This cycle looks like a gas generator cycle, it is also an open cycle. However, the turbine is not started by a small combustion chamber, but by the gases that come directly from the engine combustion chamber. Then, they are redirected to an evacuation.

The recent rocket New Shepard from Blue Origin uses the BE-3 engine, which uses the bypass cycle. According to them, this engine is very useful in the case of human space flight, because with only one combustion chamber and less complex plumbing, the engine is less stress. However, its ignition is still complex, because the gases that should make the pumps work must be taken from the combustion chamber, where the fuel comes via the pumps... Moreover, the turbine heats much more.

So, it is simple and efficient, but complex to ignite and to develop.

Expander cycle :

This cycle uses the heat from the nozzle to heat up the fuel. Then the fuel that was a liquid and now a gas (because of the heat it absorbs) will make the turbine works and will be re-injected in the combustion chamber.

By increasing the volume of the nozzle, its area will increase with a factor of 2. The volume of the fuel that flows in the pipes will, however, increase by a factor of 3. That way, there is a point where the propellant cannot, at the same time, absorbs the heat and makes the pumps work, restricting these engines to barely 300kN. As a reminder, a Merlin engine develops 935kN !

Some of these engines use gas generators to start, making the turbine works, until the propellant flowing by the nozzle will be able to keep the engine works.

One of its variants is called Expander Bleed Cycle, that will release an amount of its gases in an evacuation. By sacrificing a small amount of these gases, we can keep the operating conditions of the pumps higher (because we reduce the contrary pressures and create a depression), creating a higher thrust.

.svg/489px-Expander_bleed_cycle_(coolant_tap-off).svg.png)

The Vinci engine from Ariane6, currently in development, will use this cycle.

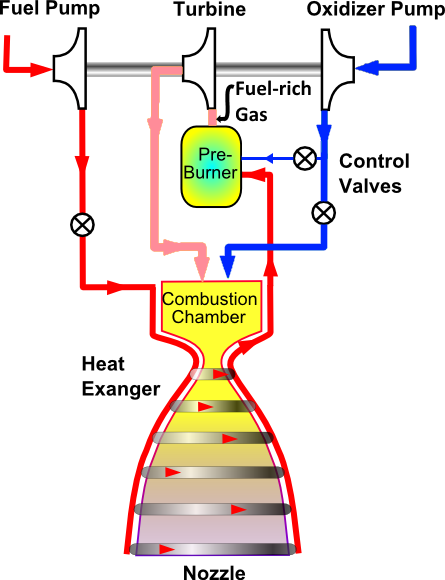

Staged combustion cycle :

This cycle looks like a closed cycle, however, ALL the fuel is use to make the turbine works in a gas generator, and it is only the exhaust gas from the generator that will burn with the oxidizer in the real combustion chamber.

This drawing looks like the drawing from the closed cycle, but if you look closely, the fuel (in red) flows only in the gas generator. Legend :

- 1 : fuel pump,

- 2 : turbine,

- 3 : combustive pump,

- 4 : gas generator,

- 5 : valves,

- 6 : combustion chamber,

- 7 : heat exchanger,

- 8 : nozzle.

Even if it is very efficient, it damages the turbine.

A dozens of engines use this cycle, among them the famous SSME, the iconic engine from the Space Shuttle !

Watch its ignition on this video in slow motion. Quite impressive, Isn't it ?

Their ignition is simple : the fuel is bring, thanks to the pressure, in the "pre burner" and ignited by a spark plug (like the ones on the cars!). This burn makes the turbo-pumps work and then, they bring the fuels in the combustion chamber to be ignited. Once the engine is started, its thrust is 2MN, and its ISP is 363 seconds. The gases are ejected at 4km.s^-1 ! It can change its thrust from 67% to 109%.

As well as the Merlin engine from SpaceX, and as we saw it in the article about the rockets guidance, they can rotate on their gimbals, to rotate the rocket.

Full-flow staged combustion cycle :

This cycle is based on the previous cycle, but it also uses a gas generator that takes all the oxidizer. With TWO small combustion chamber, each of them pumping the fluid it burns in majority (one rich in fuel, one rich in oxidizer).

So, we have two turbo-pumps, two gas generator and the combustion chamber that takes the gases from this two pumps. The system is, of course, more complex... However, thanks to this system, the turbines are cooler and less under pressure, increasing its reliability.

The Raptor engine from SpaceX, created for the BFR, currently testing, uses this cycle.

Electric pumps engines :

This technology uses an electric pump which brings the propellants in the main combustion chamber.

Powered by an electric engine and a battery, the electric pumps of these engines pressurize the propellants from a low-pressure tank to the high pressure combustion chamber.

The Rutherford engine from the Electron rocket, from RocketLab is the only rocket engine using this cycle currently in service . We are talking about it here : Space 'n' Science - RocketLab Electron !

Because of the weight of the battery to carry, the electric pump powered engines don't have as much performances as the ones powered by turbo-pumps. But their mechanical simplicity and the absence of turbomachines allow them to have reduced cost in development and production. However, they could have, in the future, better performances than the engines powered by tank pressurization and solid propellant engines, as the technology evolve.

Nozzle cooling :

As we saw it in every previous cycle, the nozzle heats up very much and must be cooled down. We can do it in different ways, either inject fuel around the nozzle or use an ablative nozzle. This means that there is a material which covers the inside of the nozzle and disintegrates when burning. The nozzle is literally burning during the flight !

We can also build a nozzle with radiative cooling or inject a cold fluid around the nozzle, which will create a cold thin layer between the flames and the metal.

Fuels :

The mix that is burned in the combustion chamber is composed of two elements : a fuel and a oxidiser . A lot of combinations have been tested at the beginning of the space area but few of them are currently used. There is a NON-EXHAUSTIVE list : (LOX means Liquid Oxygen)

- LOX-kerosene : a good compromise to have at the same time a good specific impulse and an high thrust. It's often used to power the first stage of a rocket. -LOX-LH2 : creates the best specific impulse but it needs very big tanks because of the low density of the hydrogen. Optimal to propel the higher stage of the rockets. The hydrogen infiltrate very easily everywhere, the pipes must be really waterproof. And also, H2 + O = H2O, this mix is only producing water !

- LOX-methane : close but less efficient than LOX-kerosene, it "dirty" less the engines. No engine reached the operational phase in 2016. -Hydrogen peroxide

- Oxygen-Hydrazine

- Nitrogen peroxide-kerosene

- Nitric acid-kerosene

- Nitrogen peroxide-Hydrazine

- Nitrogen peroxide-1,1-dimethylhydrazine

- C-Stoff-T-Stoff

Thrust modulation :

One of the main advantages of liquid propellant engines compared to solid propellant engines is the ability to modulate their thrust. This way we can change the acceleration that endure both the rocket and the payload ! It's also necessary when we use rocket engines to land a machine on a planet, like Curiosity on Mars or the Falcon's boosters!

The thrust modulation is created by modifying the propellant flow in the combustion chamber. However, to have a thrust that is modulable the combustion must be stable at the different supply levels which makes the engine development more difficult. Indeed, an 86% thrust could, for example, create a less stable combustion, making this power ineffective.

Engine role in the rocket orientation :

In order to correct the rocket orientation, the thrust must be able to move. The thrust of a liquid propellant rocket engine can be easily moved : actuators are used to tilt the engine with its nozzle of few degrees. With only one engine we can control the yaw and the pitch but to control the roll we must have dedicated engines.

The thrust orientation can also be done by combining the action of several specialised engines called Vernier thruster.

Nuclear engines :

Let's get out of liquid engine (finally?) and let's take a look at some... unusual engines now !

Careful, I am not talking here about RTG, these nuclear devices that are used to power Curiosity and Voyager 1 and 2 with electricity for example. No, these mini nuclear power plants are not used for propulsion !

Principle :

Here, I am interested in nuclear engine strictly speaking The nuclear thermal propulsion uses a nuclear reaction to heat a fluid.

Then, it will be ejected by the nozzle. In theory, we should reach higher ejection speed with this system than with classical engines !

In practice :

Only one ground test was considered, the NERVA engine.

.png/640px-Nerva_-_nuclear_rocket_engine_(fr).png?uselang=fr)

Nuclear propulsion is not really supported in the world because of the risks related to the launch of a nuclear device and its cost.

Ionic engines :

How could we miss ionic engines in an article about engines ?

Admittedly, they are not use on rockets but on probes.

Principle :

In an ionic engine, the fuel is not burned but ionized. The ions (electrically charged atoms) go through two electric railings and are speeded up. The acceleration strength of the ions causes an opposite reaction strength : this is the propulsion strength from the ion engine.

To keep the electrical neutrality of the probe and the fuel, the ions take back their electron at the exit of the engine. Because yes, no gas means no nozzle !

We use the xenon (a noble gas, like the helium saw earlier) as « fuel ».

The electrical energy necessary for the ionization and the acceleration of the released ions is produced thanks to solar panels.

With the engines saw previously, we need to take on board the mass to eject and the energy to eject it. But with the ionic engines, only the mass to eject is taken.

The ionic engines produce a low propulsion strength but on a very long time and are especially economical. They produce, for each kilogram of fuel on board, a quantity of work higher compared to usual engines. So, they can, after a long time, give the same speed to the spacecraft with way less fuel. Ionic engines are also much lighter (a dozens of kg), saving even more fuel.

This is the contrary of a "brutal" liquid engine, that will tolerate 2 minutes of tension and pressure, while this kind of engine will be able to stay turned on during weeks !

It has almost no thrust but a huge ISP !

In practice :

Many probes have used it : GOCE, SMART, DAWN... and even some telecommunication satellites !

These heavy satellites, saw in the article about the different orbits are about 35 786km from the Earth. They must orient and correct their orbits very finely. Such small engines are more beneficial than the cold gas ones.

Other kind of engines :

I will do a small digression about non-conventional and scientifically controversial propulsion methods.

Nuclear PULSE propulsion :

principle :

The nuclear pulse propulsion is a spacecraft propulsion that uses nuclear explosions in order to produce a thrust. You're not dreaming, the idea is to drop a series of atomic bombs to surf the wave that is created !

It was inspired by Stanislaw Ulam in 1947 and was studied as part of the Orion project in the 50s and 60s.

The Orion example :

Orion is the first try of a nuclear impulse rocket from 1950 to 1963. The rocket was releasing small directional nuclear bomb behind it and was using the blast from the explosions with a large metallic plate mounted on a shock absorber.

.png/800px-Orion_vehicule_design_(fr).png?uselang=fr)

The first adaptations of this system promised huge spacecraft able to take of from the Earth and do fast interplanetary travels with only one stage.

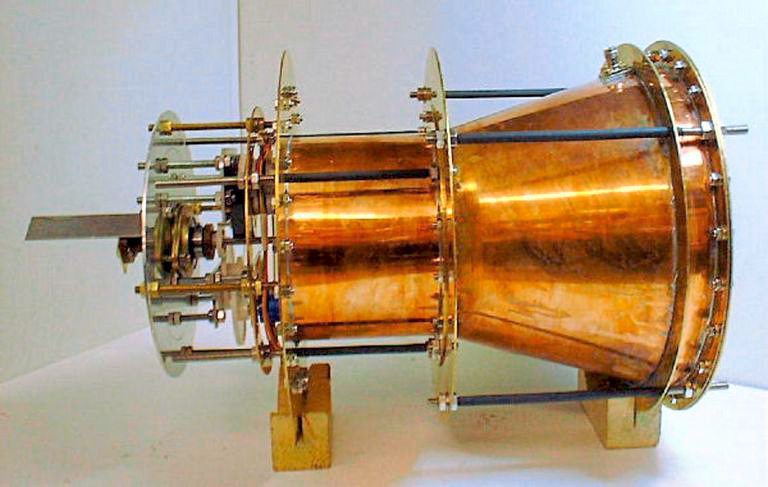

The EM-Drive :

Principle :

EmDrive (Electromagnetic Drive) or "radio frequency resonant cavity thruster", is an electric propulsion system that would create a propellant free thrust. That way it would move without losing mass. The energy conservation would not apply, that would break the law of physics.

The EmDrive was proposed in 2001 by Roger Shawyer. Such a system would create many opportunities in space travel, that's why it aroused interest especially from NASA. Since the years 2010s, the EmDrive becomes very popular.

However, there is a controversy about the theoretical impossibility with Newtonian mechanics and possible experimental errors.

Although an electric source is required, the device does not have moving parts and does not eject mass nor produce radiation outside its microwave frequency cavity.

In practice :

This device, even if it's interesting is at the same time possible and impossible, if we do not care about the energy conservation law, we can find the calculus correct, but a law is mean to be respected.

The experiments have shown a strength, indeed, but it could be experimental errors.

If you want to explore more this topic you can watch these two videos of Scott Manley:

To conclude :

As we saw it, all these engines have one goal, to produce a strength in one way and push the spacecraft thanks to the action/reaction principle.

They are of all kind, more or less expensive, efficient, useful, and simple, but all create a unique thrust and ISP.

By combining intense thrust, bigger ISP, ionic engines and cold gas, we have a combination that can bring us to the end of the solar system !

Thank you for reading,

Niels.

Translated by Nodyrus ! @Nodyrus on twitter ;)

Corrected by Arco ! @HollestelleArco on twitter ;)